APPLICATION QUESTIONS

WHAT DO I NEED TO APPLY LIZARDSKIN?

Please see our Preparation Page for a full list of equipment needed.

IF I AM USING BOTH SOUND CONTROL AND CERAMIC INSULATION, WHICH PRODUCT SHOULD I APPLY FIRST?

Always apply LizardSkin Sound Control before Ceramic Insulation. Be sure to wait 24-36 hours in between applying Ceramic Insulation on top of Sound Control. To view the entire application process, visit our Application Page.

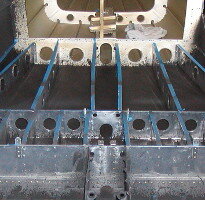

WHAT PARTS OF THE CAR/TRUCK DO YOU APPLY IT TO?

For best results, it is recommended to coat the entire interior with both Ceramic Insulation and Sound Control. Typical applications for both products include firewalls, floor pans, transmission tunnels, doors, hoods, trunk lids, under headliners, inside fenders, panel van walls and any other areas that allow heat and/or sound into the interior.

CAN IT BE USED AS A BED LINER?

We do not recommend the use of LizardSkin Ceramic Insulation or Sound Control as a bed liner. Although the products are very tough and durable, they are not designed to withstand the rigors that bed liner materials are subject to.

CAN LIZARDSKIN GO ON TOP OF A BED LINER PRODUCT (RHINOLININGS®, LINE-X®, ETC)?

No, LizardSkin should not be placed on top of a bed liner. While LizardSkin is very durable, it is not as hard as the liner products. Either coating can be applied PRIOR to application of a bed liner in certain applications but ensure that the LizardSkin is completely cured first (24-48 hours).

CAN IT BE USED AS AN UNDERCOATING TO PREVENT STARRING?

Yes, both LizardSkin Ceramic Insulation and LizardSkin Sound Control can be used on the interior or exterior of the vehicle. At the recommended thickness, the coatings can prevent starring from normal road debris. For additional toughness, LizardSkin TopCoat is available.

CAN LIZARDSKIN PRODUCTS BE USED TOGETHER?

For maximum sound control and insulation performance, both LizardSkin Ceramic Insulation & Sound Control may be used, but it is important that LizardSkin Sound Control be applied prior to application of LizardSkin Ceramic Insulation. Once both are correctly applied and fully cured (48 hours), you can use LizardSkin TopCoat to add durability, traction, and a glossy appearance.

CAN I MIX THE PRODUCTS TOGETHER SO I SPRAY THEM BOTH AT THE SAME TIME?

The products CANNOT be mixed together because Ceramic Insulation and Sound Control are two different formulations.

CAN YOU PUT IT ON THE INSIDE AND OUTSIDE OF THE FIREWALL, TRANSMISSION TUNNEL AND FLOOR BOARD?

Yes, both products can be applied on either side of the metal.

DOES THE SUBSTRATE NEED ANY PREPARATION BEFORE APPLICATION OF LIZARDSKIN?

Surface must be clean, dry, and free of rust, oil, and grease. Different levels of surface prep may be required to achieve a clean, dry surface.

Bare steel requires an automotive primer. High gloss primers and painted surfaces may require a scuffing prior to application.

Will not adhere silicone seam sealers. Contact LizardSkin for further instructions.

Fiberglass, wood, plastic, and stainless steel may need to be scuffed. Make sure any residual dust or particulates are cleaned off the surface before applying LizardSkin.

When applying LizardSkin over a rust encapsulator or similar type of coating, you need to use a primer manufactured or approved by that company and applied according to their instructions before applying LizardSkin. After applying the primer, it may need to be scuffed.

Mask off all areas not intended to be sprayed with LizardSkin.

Use aluminum foil or newspaper and painter’s tape to cover irregular shaped components, including; steering columns, brake and throttle pedal assemblies, wiring, suspension components, and any screw holes or threaded holes.

HOW LONG DO YOU WAIT IN BETWEEN COATS?

Time between coats is dependent on temperature and humidity but will usually fall between 1 and 2 hours. The best way to test is the 90-degree thumb test. Place your thumb on the first coat and twist 90 degrees. If no coating is apparent on your thumb and the coated surface is not pliable, it is ready for the next coat. If you are applying LizardSkin Ceramic Insulation on top of LizardSkin Sound Control, you must allow the Sound Control a full 24-36 hours of drying/curing time before application of Ceramic Insulation. Cure times may be prolonged in colder temperatures and higher humidity. Both Ceramic Insulation and Sound Control have unlimited recoat windows. Just make sure the coated surface is clean and dry.

CAN I ROLL OR BRUSH THIS PRODUCT ON?

We strongly recommend that the LizardSkin products be applied with the LizardSkin SuperPro Spray Application Kit. Small applications of less than 1 square foot can be brushed, though sanding after each coat may be required to ensure even coats. Please call for further instructions.

CAN I USE A SCHUTZ (UNDERCOATING) GUN TO APPLY LIZARDSKIN?

We strongly recommend against using these types of sprayers to apply LizardSkin because the pick-up tube and nozzle are not big enough to properly handle the thick, viscous consistency of LizardSkin Sound Control and Ceramic Insulation. Clogging and splattering can be a constant issue when using that type of sprayer. We specially manufacture the SuperPro Application Sprayer to allow the coating to apply cleanly and uniformly without clogging or splattering.

WHAT TEMPERATURE SHOULD YOU APPLY LIZARDSKIN?

Both the metal substrate and air temperature must be greater than 60˚F (15˚C) to allow the coating to properly cure. It is ideal for the temperature to be above 70˚F (21˚C). The higher the temperature, the faster the drying and curing.

How do I mix LizardSkin when it’s in the pail?

Please use the red mixing paddle provided with the SuperPro Application Kit attached to a variable-speed drill. Mix the product at low speed (less than 300 RPM) moving the paddle up, down, and around until it reaches a smooth consistency. Normal mix time is less than one minute. If you do not have one, you can contact us at 800-549-0042 to get a replacement paddle.

CAN I THIN LIZARDSKIN WITH WATER TO MAKE IT GO FURTHER?

NO. Thinning LizardSkin will greatly reduce its effectiveness. The addition of water will affect both adhesion and insulation properties. If you feel thinning is necessary, contact LizardSkin for further instructions.

CAN LIZARDSKIN BE SPRAYED ON PLASTIC?

Yes, but the surface may need a light scuffing prior to application. You will also need to wipe off any residue the scuffing leaves behind.

CAN I ORDER PARTS FOR MY SUPERPRO SPRAY GUN?

LizardSkin does not carry/sell replacement parts for the SuperPro sprayer. If you need to order a replacement gun, be sure to tell us why so that we can identify any defects.